Wastewater process intensification (or wastewater treatment intensification) is the use of new technologies or modifications to existing processes to improve the efficiency and effectiveness of the treatment of wastewater. It can lead to several benefits, including:

- Reduced energy consumption: Process intensification can help to reduce the electricity needed to treat wastewater. This can save money and reduce greenhouse gas emissions.

- Reduced chemical use: Process intensification can help to reduce the amount of chemicals needed to treat wastewater. This can save money and reduce the environmental impact of wastewater treatment.

- Improved effluent quality: Process intensification can help to improve the quality of the effluent from wastewater treatment plants. This can make the effluent more suitable for reuse or discharge to the environment.

- Increased treatment capacity with the same footprint: Process intensification can help keep treatment capacity at a higher rate while enabling facilities to reduce expansion needs. This can save money and make it easier to site new plants.

What Technologies Can Be Used for Wastewater Process Intensification?

There are a number of different technologies that can be used for process intensification in the treatment of wastewater. Some of the most common technologies include:

Membrane Bioreactors

Membrane bioreactors use membranes to separate solids from wastewater. This allows for more efficient treatment of wastewater and can lead to reduced energy consumption and chemical use.

Anaerobic Digestion

Anaerobic digesters use microorganisms to break down organic matter in wastewater. This can help to improve the quality of the effluent and can also produce biogas, which can be used to generate energy.

Advanced Oxidation Processes

Advanced oxidation processes use chemicals or electricity to break down pollutants in wastewater. This can help to improve the quality of the effluent and can also make it more suitable for reuse.

Nanobubble Technology

Nanoscopic bubbles act like clean chemistry to improve biological process performance by removing inhibitory contaminants, allowing plants to reduce energy and chemical usage, eliminate odors, foams and scum and increase process intensification and capacity.

More on Nanobubble Technology for Process Intensification

The unique properties of nano-sized bubbles allow for a new process step in wastewater treatment plants, which results in increased plant capacity and resiliency while reducing costs and carbon footprint.

Moleaer’s technology uses air and water to generate in-situ clean chemistry, which selectively targets contaminants that cause inefficiencies and odors in wastewater treatment.

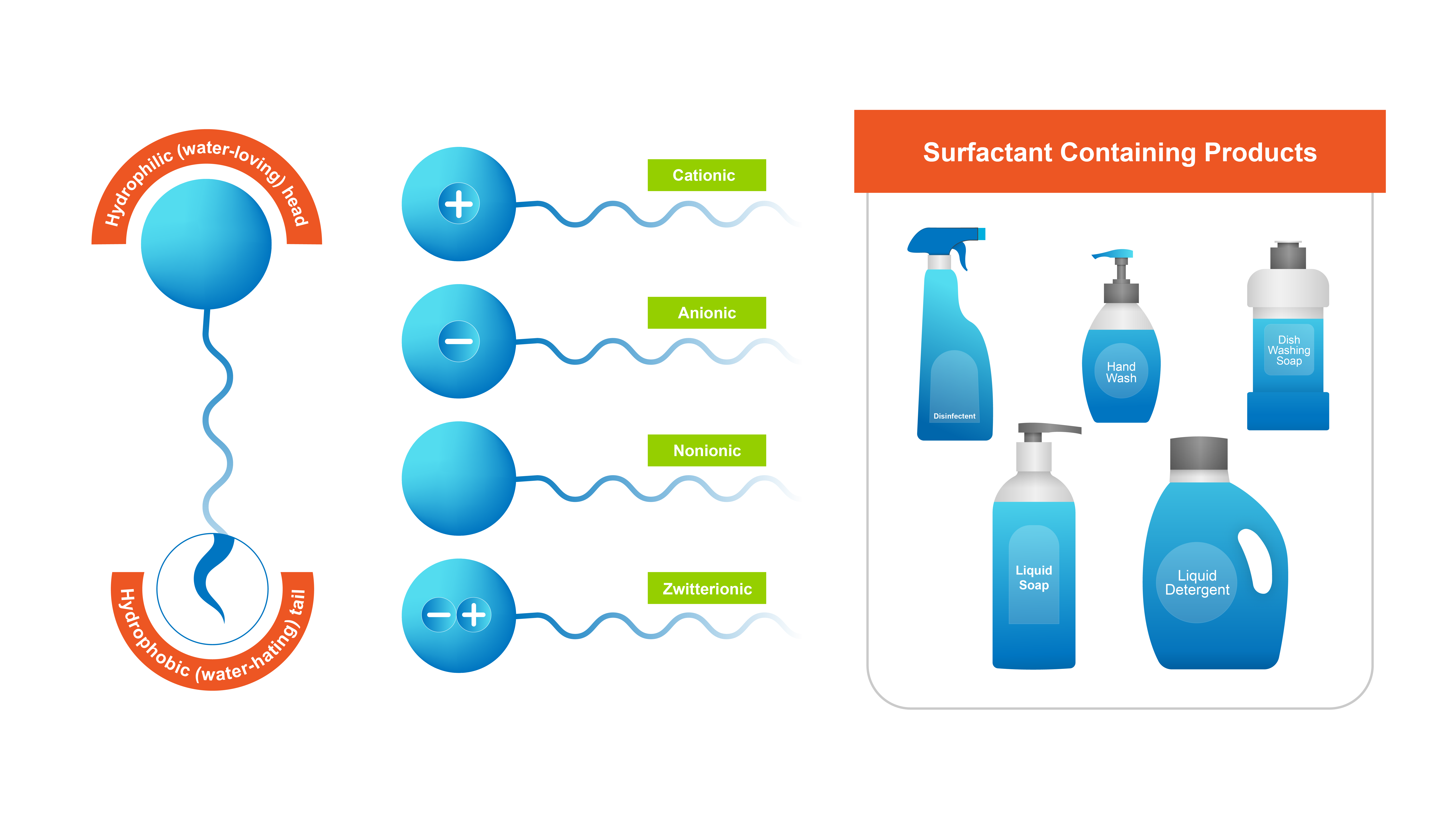

“Surface-active-agents,” also known as surfactants or tensides are among these contaminants that negatively impact wastewater treatment processes when found in high concentrations. While surfactants help to clean, they can also stabilize emulsions of oil and water, making them more difficult to break down. This can lead to a fatberg, a hard mass of waste matter that collects and clogs sewer systems, formation. In literature, it has been shown that concentrations exceeding 15 mg/L of SLS reduce oxygen transfer efficiency by 50%, compared to clean water.

In low concentrations, surfactants can be treated using traditional aerobic biological systems. However, in most wastewater facilities, these concentrations exceed design limits, causing many of the issues highlighted earlier.

Nanobubbles, when deployed in the right locations, have unique characteristics that can break down and remove surfactants. This reduces their concentrations, enhancing the treatment ability of wastewater plants, without any drawbacks.

Nanobubble technology delivers a multi-pronged approach to improve the performance and efficiency of wastewater treatment by removing these inhibitory contaminants to make wastewater easier to treat. Pretreating wastewater with air nanobubbles upstream of an activated sludge process:

- Improves biological process performance

- Increases secondary treatment capacity

- Decreases chemical demand

- Reduces aeration power draw by helping increase oxygen transfer efficiency

- Reduces odors, foams and scum

Instead of investing in expensive construction projects or continuing to increase operations and maintenance (O&M) budgets to cover uncontrolled costs, wastewater treatment plants are improving their existing processes with nanobubble treatment. These benefits include:

- Process intensification

- Increased treatment capacity

- Smaller process unit footprint and ancillary equipment

- Improved energy efficiency

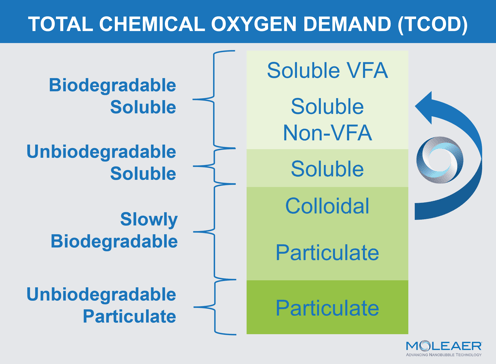

- Improved BOD, COD, and nutrient removal efficiencies

- Less chemical usage

- Increased primary and secondary treatment process efficiency

- Better, more consistent effluent water quality

Nanobubble Technology Process Intensification Case Study

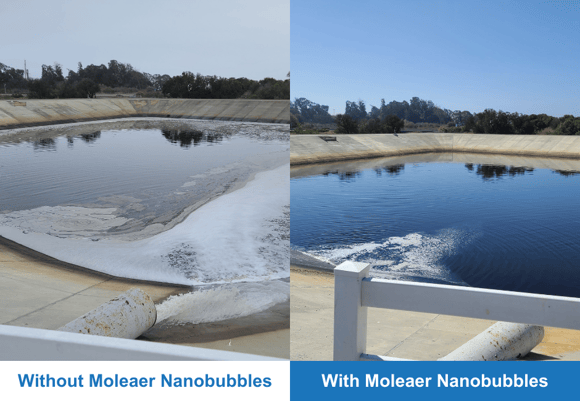

Goleta Sanitary District | Nanobubbles Remove Inhibitory Compounds for Better Treatment Efficiency

At a water resource recovery facility in Goleta, California, nanobubbles pretreat 4.2 million gallons per day (662 m3/hr) average annual dry weather flow (AADWF) of raw, screened wastewater downstream of grit removal and upstream of primary clarification. This nanobubble pretreatment has enabled process intensification at Goleta by increasing treatment capacity and efficiency.

The Year Over Year Results:

- 57% average reduction in YoY aeration energy

- 64% average increase in YoY BOD removal efficiency, measured as a pound of BOD removed per kWh electricity

Results During the Pilot Period:

- 43% reduction in aeration power draw

- 44% decrease in chlorine demand

- 20% increase in secondary treatment capacity

- 10% increase in primary clarifier solids removal

Stavnsholt Wastewater Treatment Plant | Nanobubbles Eliminate Foul Odors While Enabling Process Intensification

Another wastewater treatment plant was able to solve its odor issues and improve efficiency. Stavnsholt, a 0.7 MGD (110 m3/hr) plant located in Denmark, faced significant odor issues that weren’t fixed with typical treatments. They installed Moleaer’s nanobubble generator to mitigate these problems, resulting in additional process intensification.

The Results:

- Increased solid removal efficiency

- Increased sludge dry matter content by about 13%

- Increased methane in the biogas produced by 5%

- Reduced aeration electricity usage by 5.3%

- Reduced ferric chloride usage for H2S control by 82%

What are the Benefits of Wastewater Process Intensification?

Process intensification is a growing field of research and development. As new technologies are developed, process intensification is becoming an increasingly viable option for improving the efficiency and effectiveness of wastewater treatment plants.

Here are some additional benefits of process intensification in wastewater treatment:

- Improved public health: Process intensification can help to reduce the spread of diseases by removing pathogens from wastewater.

- Increased water reuse: Process intensification can make it possible to reuse treated wastewater for irrigation, industrial processes, or other purposes. This can help to conserve water resources.

- Reduced environmental impact: Process intensification can help to reduce the amount of pollutants that are released into the environment. This can improve air and water quality and protect wildlife.

Charting a Sustainable Future with Wastewater Treatment Process Intensification

Overall, process intensification is a promising approach to improving the sustainability and efficiency of wastewater treatment. It has the potential to reduce costs, improve environmental performance, and protect public health. To learn more about Moleaer’s nanobubble technology, visit our website at www.Moleaer.com.