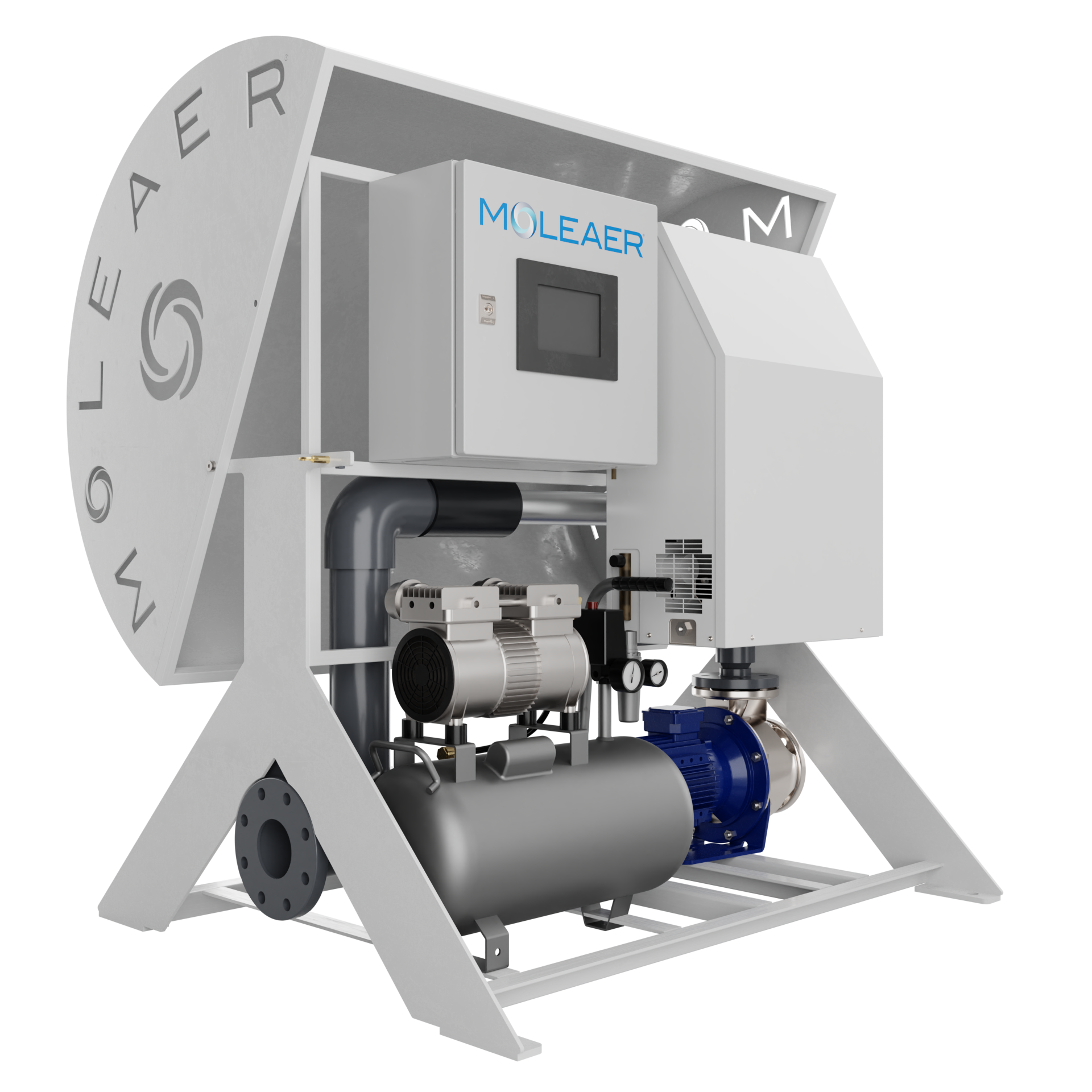

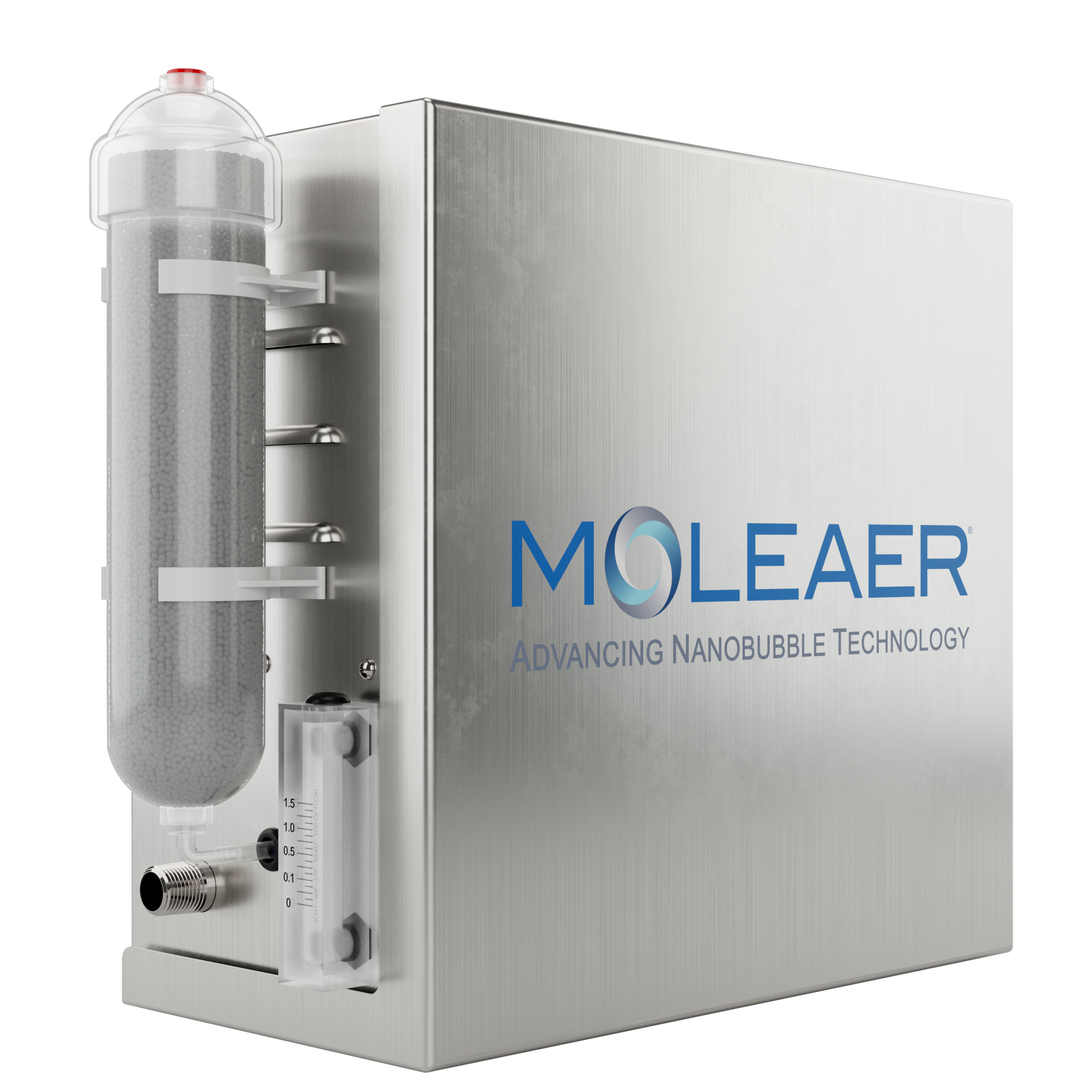

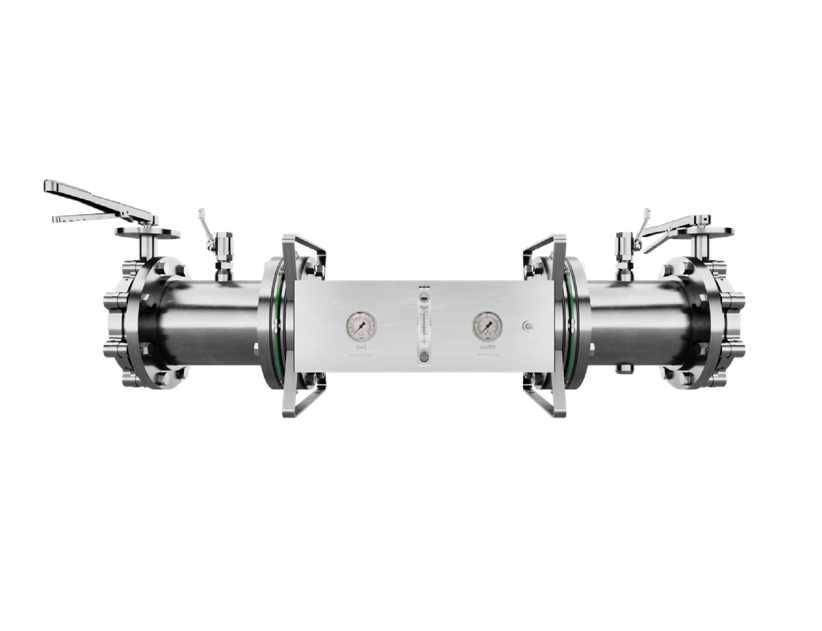

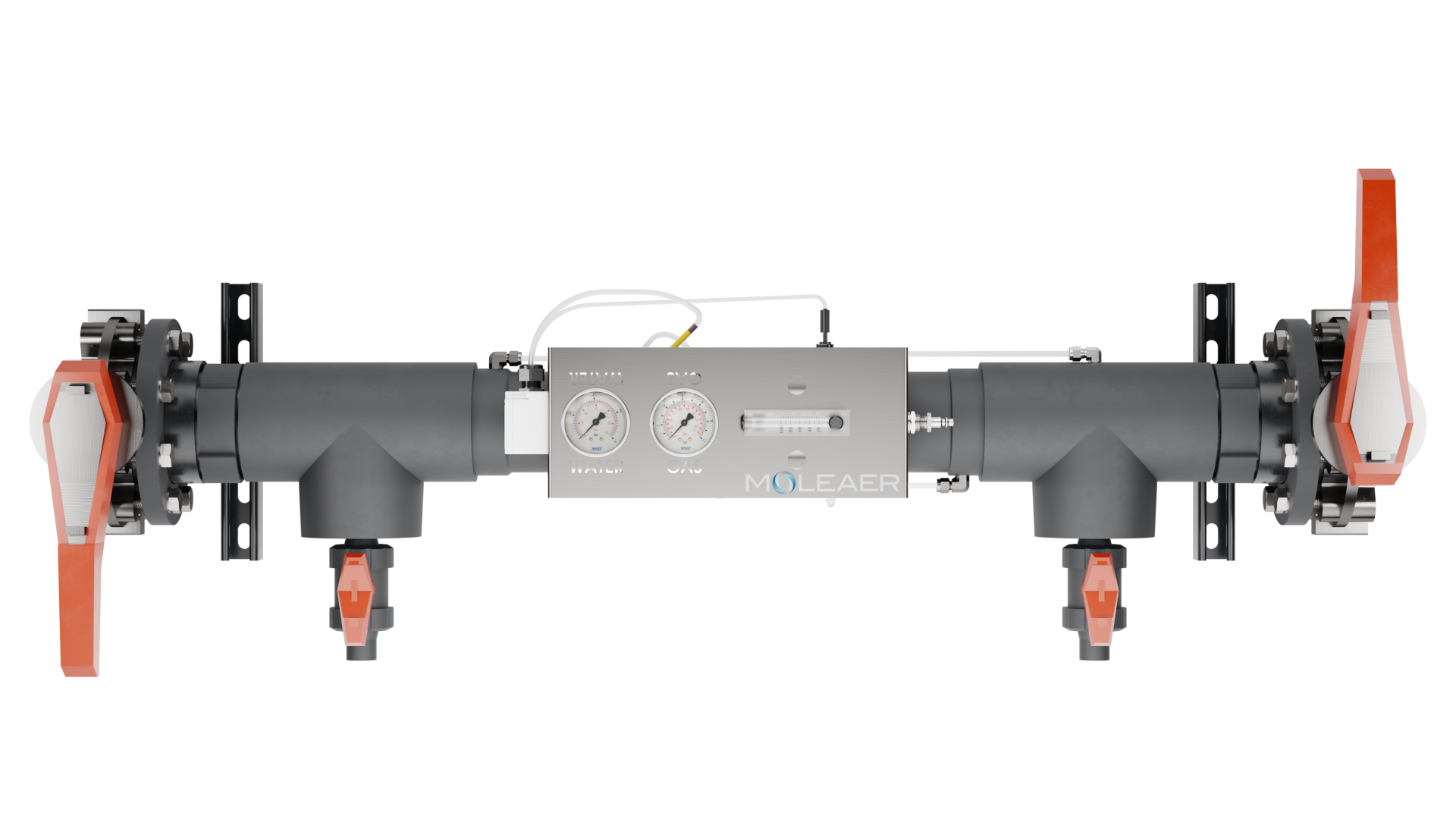

Precision Nanobubble Technology, Tailored to Your Operations

Moleaer nanobubble generators inject gases into liquids with unparalleled efficiency and precision. With both standard systems and customizable solutions available, our technology delivers unmatched benefits in every application. Engineered for seamless integration and straightforward installation, we accommodate versatile flow rates, volumes and gas types.

-1.png)

.png)

.png)

.jpeg?width=1559&height=1170&name=Neo%20(2).jpeg)

-2.png)

.png)

%20(1).png)

.jpg?width=788&height=486&name=Moleaer%20advertorial%20editie%20juni%202024%20(004).jpg)