Best Disinfection at the Lowest Cost with Ozone Nanobubbles

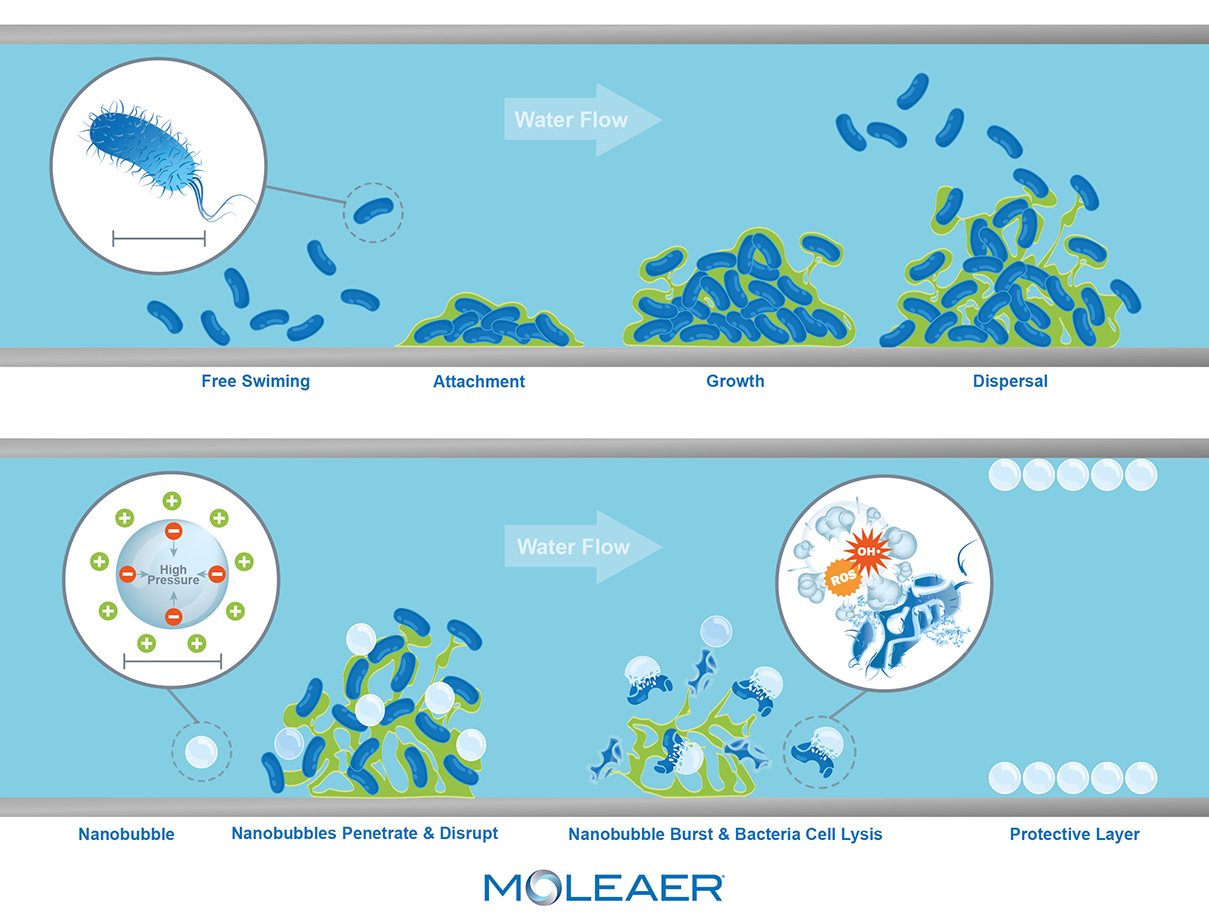

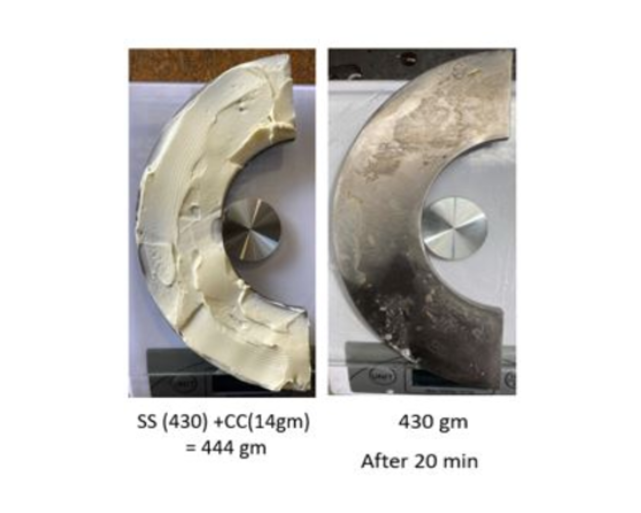

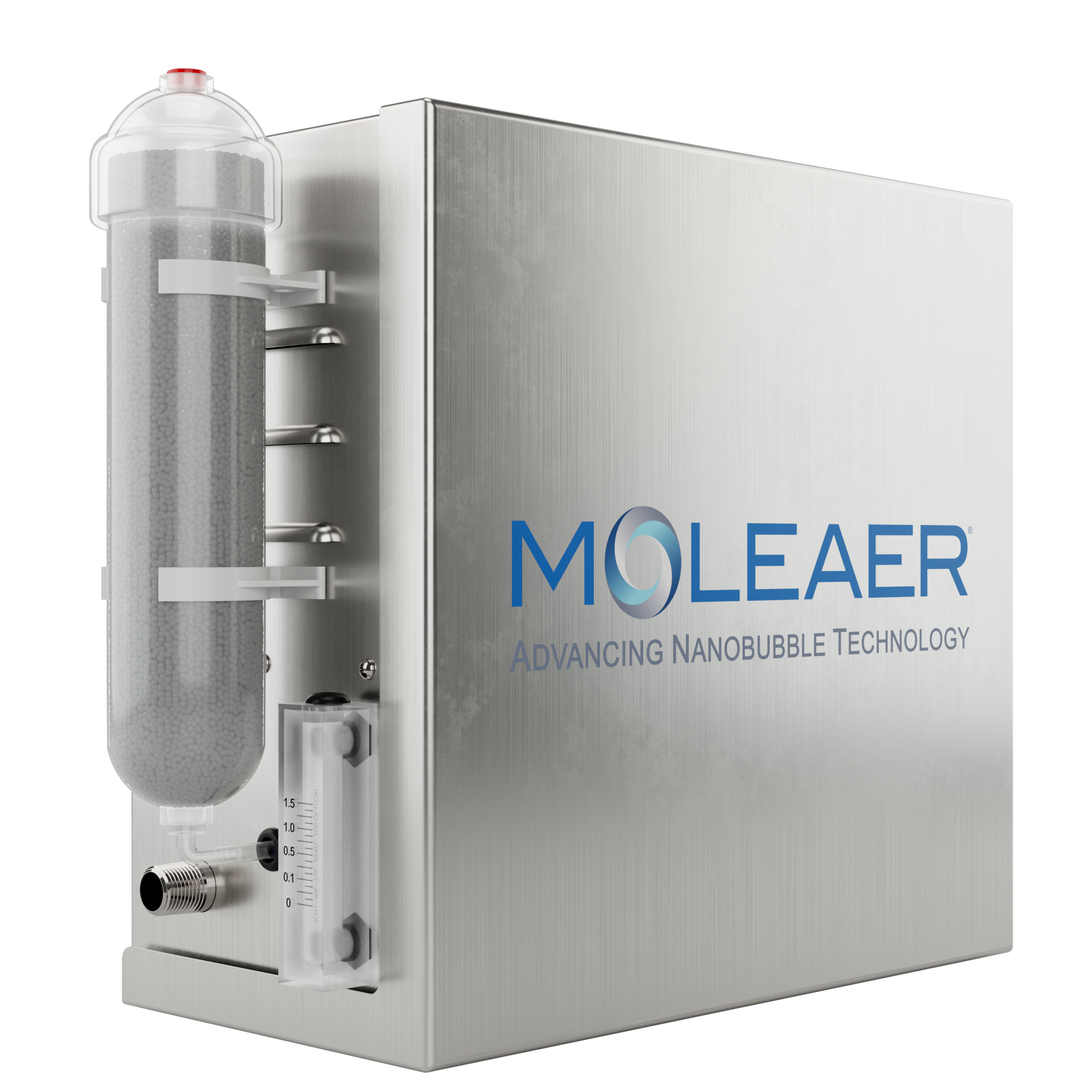

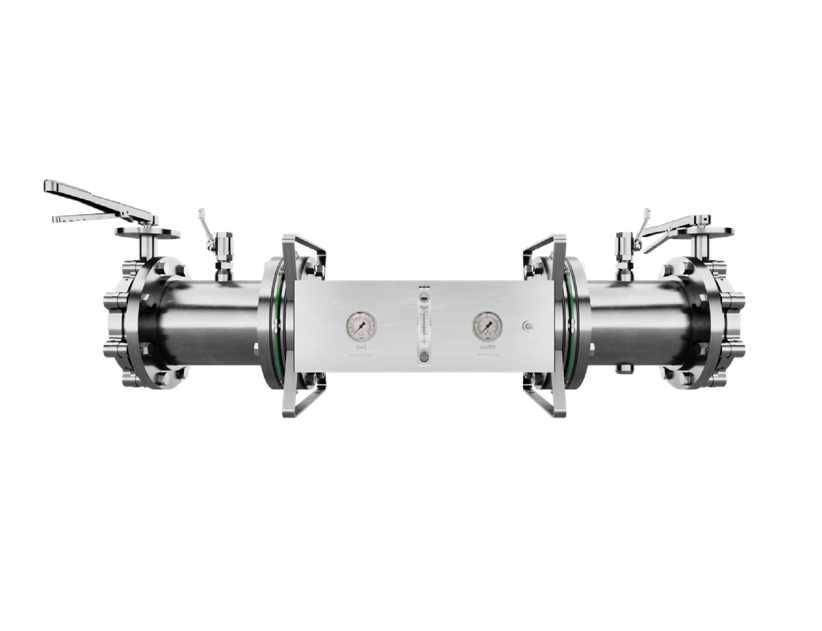

Elevate your foot safety standards without harsh chemicals through the power of ozone nanobubbles. Moleaer nanobubble technology minimizes ozone waste, making every drop count, to provide the highest disinfection efficacy at the lowest cost on the market. With simple solutions for food prep sinks that enable continuous and automated ozone nanobubble sanitation to enhanced food processing and clean-in-place procedures, reducing biofilm and increasing operational efficiency, Moleaer’s ozone nanobubble products offer the most effective use of ozone in the food and beverage industry.

-1.png)

.png)

.png)