Moleaer nanobubble technology delivers unparalleled improvements in aquaculture, including oxygen transfer efficiency, rearing water quality, and feed conversion ratios at the lowest total cost.

Talk to an ExpertImproved water quality and ammonia removal contributed to fish welfare and growth at well-known aquaculture facility in Norway.

See the full report

A hyper-efficient, easy-to-integrate and retrofit-capable system enables immediate distribution of super-oxygenated water when it matters most. Moleaer’s Trinity nanobubble generators allow wellboat and de-licing operators to replace existing underperforming injectors to increase uptime and fish welfare during critical fish crowding operations, such as de-licing or fish transport. Nanobubble technology allows fish farming crews to improve oxygen use efficiency while maintaining optimal dissolved oxygen levels during the crowding procedure, ensuring fish welfare by significantly reducing stress levels and mortality rates.

Nanobubble oxygenation delivers quick and immediate oxygenation to crowded fish during treatments, while utilizing dramatically less oxygen. Optimizing levels of oxygen during treatment lowers fish stress levels and enables longer and more effective treatments. Permanent or mobile nanobubble systems enable rapid and effective solutions for improved health treatments.

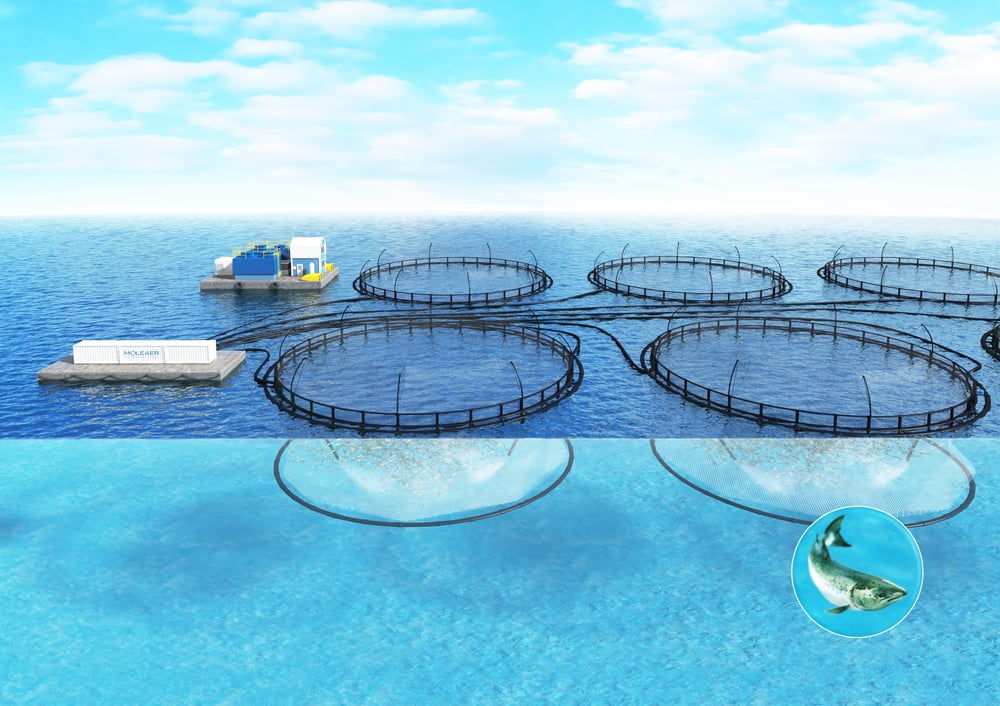

Whether your needs are temporary, seasonal, or permanent, Moleaer has the perfect solution to meet all your aquaculture net pen oxygenation requirements. Our state-of-the-art nanobubble systems are designed to deliver exceptional performance in any scenario. From energy-efficient submersible systems that excel in deep-water applications to centralized surface-mounted systems offering high flow rates and unparalleled efficiency, Moleaer has transformed offshore oxygenation to significantly reduce costs.

Discover the extraordinary power of Moleaer's dissolved oxygen and oxygen nanobubble combination for your aquaculture net pen. Experience a multitude of benefits that promote the well-being of your farmed fish. Our systems establish a stable, evenly oxygenated environment, optimizing dissolved oxygen levels to minimize stress, maximize feed conversion rates, and deliver superior results. Elevate your fish farming operation with Moleaer to improve input efficiency and reduce operational costs.

Moleaer systems provide your operation with oxygen – reliably and exactly when it’s needed – regardless of your present setup. Are you in need of some additional oxygenation power or does your current system require a redundancy? The Trinity nanobubble generator system is perfectly adapted to function as a redundancy or emergency oxygenator, is highly energy-efficient and can be retrofitted easily to any existing set-up, without going through the hassle of re-designing or reworking your current aquaculture farming system.

Preserving marine ecosystems is critical to sustainable aquaculture. Oxygen nanobubbles can be applied at depth of up to 100 meters, where they can blanket the benthic layer in an oxygen-rich environment to oxidize contaminates and pathogens. Moleaer’s nanobubble technology is actively used in many regions in Chile to responsibly remediate seabeds after or during fish farming operations, helping to repair damaged environments and restore flora and fauna on the ocean floor.

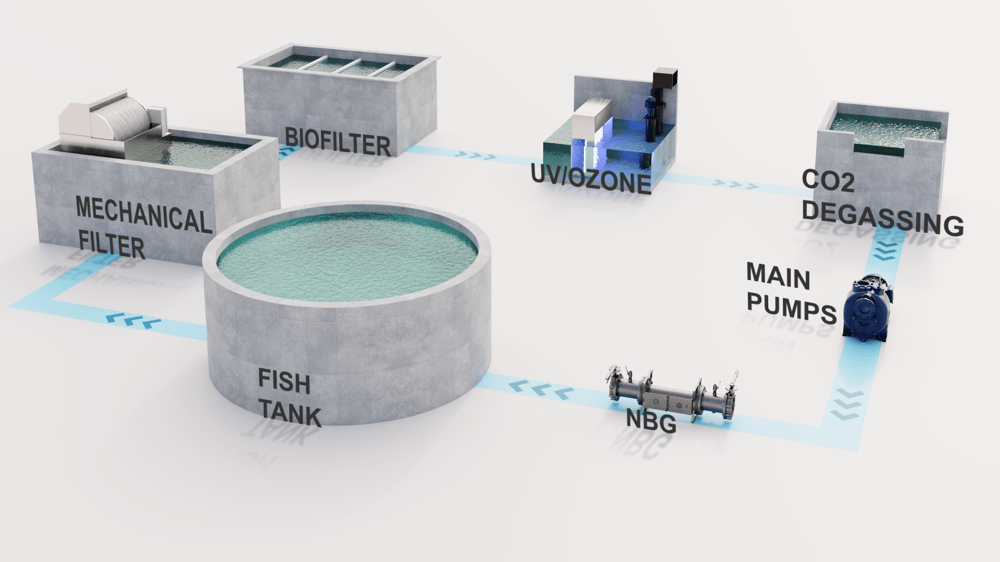

From RAS to flow-through hatcheries and fisheries, Moleaer's technology is used in land-based aquaculture systems to help maintain water quality and provide efficient and cost-effective oxygenation.

Treating all forms of water and wastewater with nanobubbles is Moleaer’s specialty. Beyond efficient oxygenation, the unique properties of nanobubbles play a critical role in addressing water quality challenges in recirculating aquaculture systems. Through hundreds of installations, Moleaer’s team has developed specific knowledge of how to utilize and integrate nanobubbles into into the RAS process to improve oxygenation efficiency and the removal of particulates, nutrients, proteins, biofilm and pollutants, as proven in a recent case study where a RAS facility achieved significant improvements in water quality and biofilter efficiency. Oxygen nanobubbles also enhance oxidation processes like UV and ozonation to improve microbial load reduction and off-flavor compound removal.

Read the Case Study

Moleaer’s Trinity nanobubble generators provide the broadest, most flexible solution for permanent or supplemental oxygen to flow-through systems. With a small footprint, low headloss, variable orientation and industry-leading flow range, the nanobubble generators can be installed directly inline, on a bypass, or in a dedicated loop. Flexible flow rates and simple ramp-up or ramp-down enable energy and oxygen usage to closely match your oxygen demand without waste or outages. Whether the requirement is to retrofit an existing facility to replace aging and underperforming fishery equipment or to help a facility meet higher production output, Moleaer’s Trinity systems are the quickest and most cost-effective solution to improve oxygen utilization and lower production costs.

Download the Case StudyLearn how nanobubbles can improve your aquaculture operations and help you reduce costs.

Talk to an Expert