Robust, Chemical-Free Wastewater Solutions with Moleaer

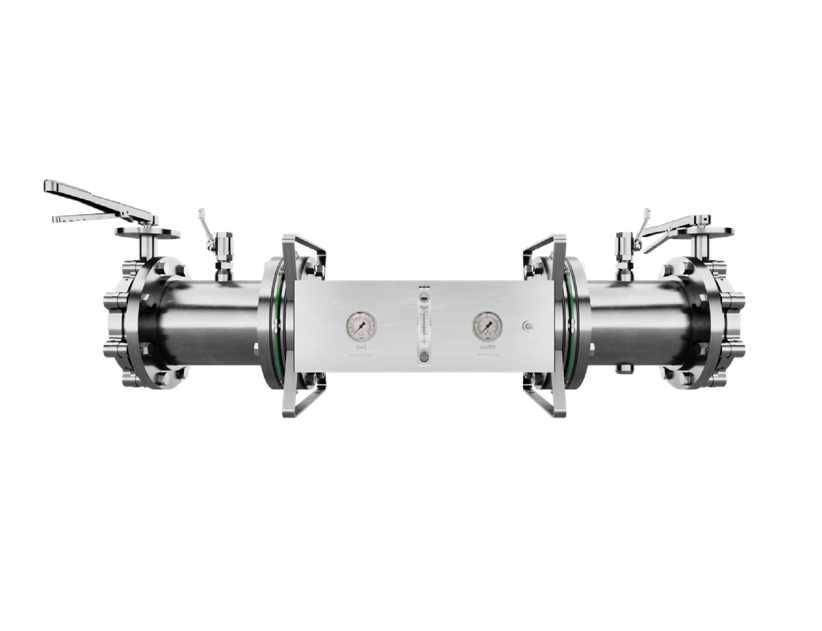

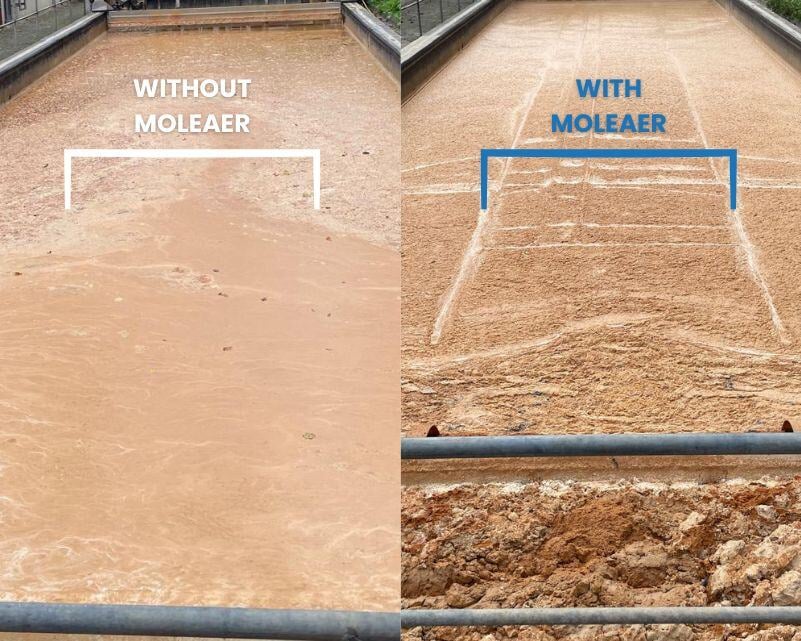

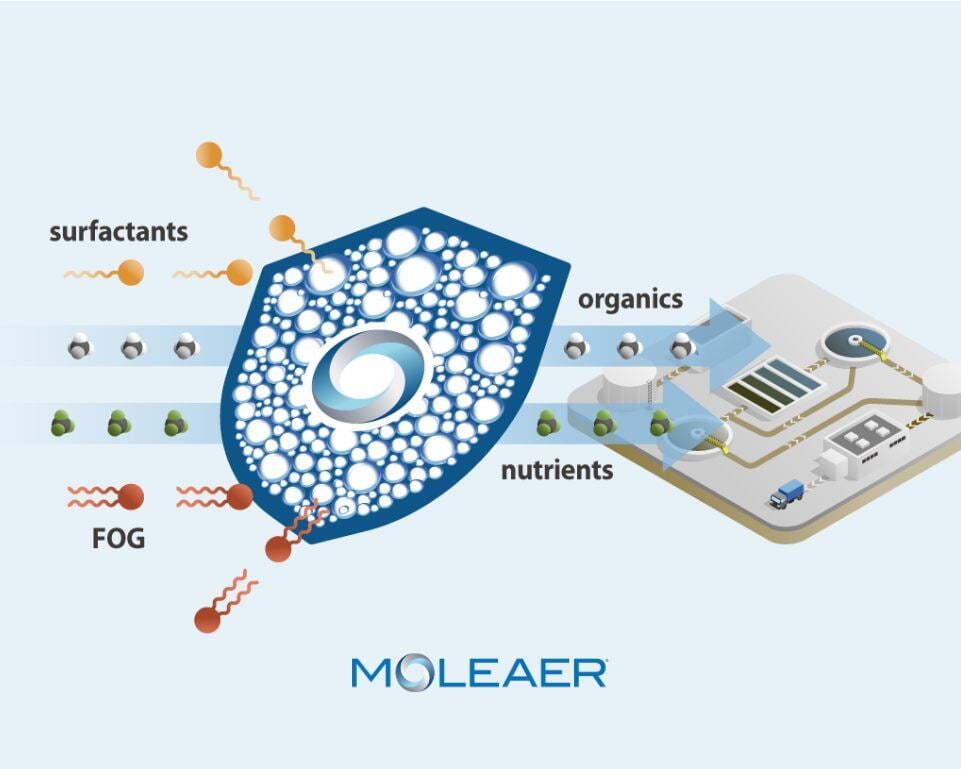

Moleaer nanobubble generators integrate seamlessly into existing wastewater treatment facilities and lagoons through flexible installation options, including inline systems or mobile trailer/containerized units. Our experienced water process engineers work with you to design the optimal configuration for your specific needs.

With minimal retrofitting required, Moleaer nanobubble solutions help unlock your plant's full potential while addressing modern wastewater challenges. Simple maintenance requirements ensure you can harness the power of nanobubble technology with minimal operational impact.

-1.png)

.png)

.png)

.png?width=1000&height=563&name=Titan%20Wastewater%20(1).png)

.png)

.png)

.png)

.png)

%20(1).png)